- current location:

- Home

- >

- News

- >

- Industry News

-

What type of respiratory protection should we choose for confined space operations?

Respiratory protective equipment is the defense of oxygen-deficient air and airborne pollutants into the respiratory tract protective equipment, is one of the important protective equipment for confined space operations, according to the method of respiratory protection, is divided into two categories of filtration and isolation.There are many types of respiratory protective equipment, each of which has its own scope of application and limitations, and it is necessary to select suitable respiratory protective equipment according to the safety risks of confined space operations. Since there may be risks of oxygen deficiency and sudden increase in the concentration of toxic, hazardous, flammable and explosive gases in a limited space, the use of filtered respiratory protective equipment such as gas masks is not recommended.For isolated respiratory protective equipment, it is also necessary to select appropriate respiratory protective equipment according to the actual operation and the purpose of the equipment. For example, the self-priming long tube respirator, due to its use in the process can not always maintain the mask for the micro-positive pressure, when the mask to form a negative pressure environment in the confined space gas may enter the mask, a threat to the user's safety and health, so it is also not recommended to be used in the confined space operation.

The maintenance of respiratory protection equipment in industrial and trade enterprises should pay attention to the following aspects.

(1) Arrange for personnel to be responsible for the maintenance of respiratory protective equipment and provide maintenance personnel with training in maintenance methods.

(2) Respiratory protective equipment should be kept in its original packaging for safekeeping as far as possible and stored in a cool, ventilated place to avoid exposure to high temperatures or exposure to the sun.

(3) Respiratory protective equipment involving compressed gas cylinders, cylinders should be sent to a qualified unit for inspection once every three years.

(4) Usually use a wet towel to wipe the product can be, prohibit water washing, prohibit the use of strong acid, strong alkaline cleaning agent or organic solvents scrubbing.

(5) Non-professionals should not change parts on respiratory protection.

Previous What are the safety risks associated with confined space operations?

Next Revolutionizing work at height: smart safety harnesses

more about [confined,space,operation,gas,detection,hazardous,gas,confined,space]:

• Confined space operation meets hydrogen sulfide poisoning, how to respond scientifically?

• How to do a good job of confined space operation protection

• Safety Protection and Emergency Rescue for Confined Space Operations

• A Cautionary Tale of Accidents in Confined Space

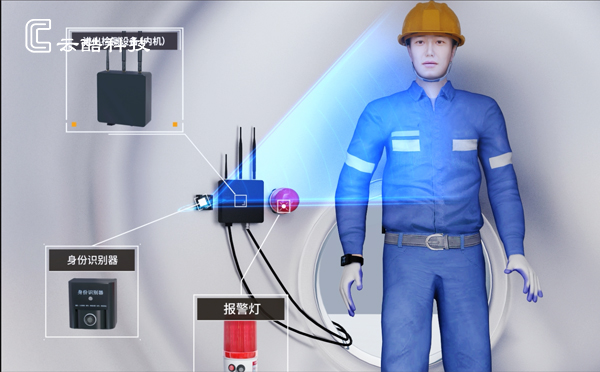

• Yunku Tech's Confined Space Monitoring Equipment: Intelligent Solutions to Guard Operational Safety and Efficiency