- current location:

- Home

- >

- News

- >

- Industry News

-

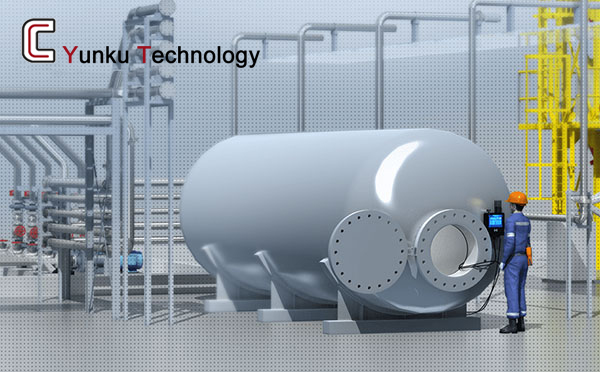

Yunku Tech's Confined Space Monitoring Equipment: Intelligent Solutions to Guard Operational Safety and Efficiency

In petrochemical, municipal engineering, energy and power fields, confined space operations (such as storage tanks, pipelines, underground well chambers) are an important part of daily operation and maintenance. However, traditional operation methods often face pain points such as insufficient ventilation, many safety hazards and low efficiency. Yunku Tech is deeply committed to the field of industrial safety and has launched a new generation of intelligent confined space monitoring equipment solutions, which are empowered by science and technology to create a new mode of safe, efficient, and compliant operations.

I. The core advantages of Yunku's confined space monitoring equipment

1. All-round safety protection system

Integrated multi-parameter gas detector, real-time monitoring of oxygen, combustible gas, hydrogen sulfide and other key indicators, exceeding the standard automatic alarm. Real-time gas data monitoring, once abnormal, the operator can instantly receive alarm information through the bracelet, remote monitoring personnel, on-site supervisors can monitor the large screen, confined space external equipment, instantly receive alarm reminders, make emergency treatment.

2. High-performance operational support

Lightweight design, the weight of the equipment is 40% less than traditional models, a single person can be quickly deployed.

Support wireless data transmission, real-time synchronization of operation data to the cloud, managers can remotely monitor the progress.

Compatible with a variety of industrial scenarios.

3. Intelligent management platform

Through the Yunku IoT management platform, it realizes equipment status monitoring, maintenance warning, and traceability of operation records.

Generate visualization report to reduce the safety risk of confined space operation.

II. Application Scenarios: Provide accurate answers to industry pain points

Petrochemical industry: avoid personnel exposure to toxic environment during tank cleaning and testing.

Municipal maintenance: reduce downtime and improve the efficiency of municipal services during the maintenance of underground pipeline networks.

Power system: prevent personnel from working safety risks when working in confined space of substation.

Previous Choosing Smart Safety Harnesses for Construction Sites

Next Factors affecting the use of smart safety harnesses

more about [confined,space,operation,gas,detection,hazardous,gas,confined,space,monitoring]:

• Confined space operation meets hydrogen sulfide poisoning, how to respond scientifically?

• How to do a good job of confined space operation protection

• Safety Protection and Emergency Rescue for Confined Space Operations

• A Cautionary Tale of Accidents in Confined Space

• Sewer pipeline confined space operations to build life defences